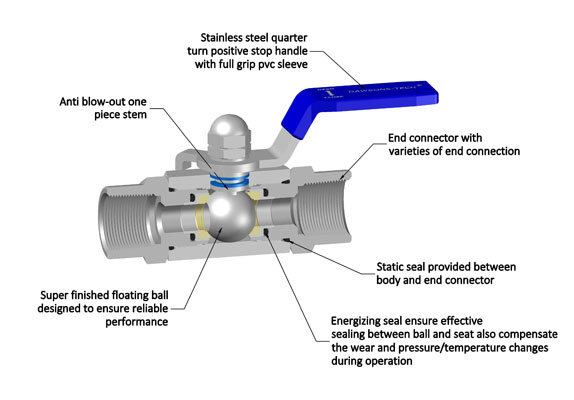

Ball Valves Series : VB41, VB43, VB45 and VB47 with ‘O’ Ring energized PTFE / PEEK Seat.

DAWSONS-TECH® Three Piece bi-directional Flow Ball Valves have been designed with ‘O’ Ring energized PTFE / PEEK Seat which ensures 100% bubble tight shut-off and continuous repeatable performance for medium pressure rating UPTO 3000 PSIG (206 Bar).

Construction & Features of Ball Valves with ‘O’ Ring energized PTFE / PEEK Seat

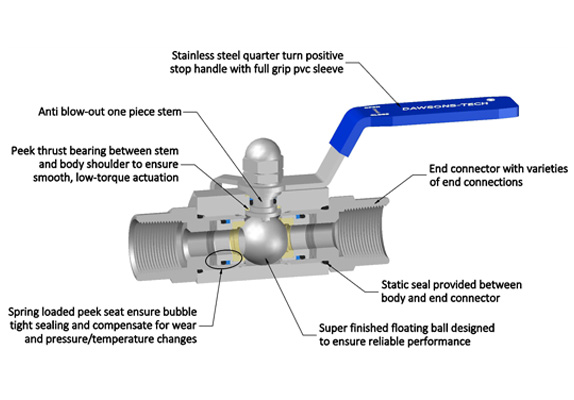

Ball Valves Series : VB71, VB81 and VB91 with Live Load PEEK Seat.

DAWSONS-TECH® Ball Valve have been designed for pressure rating UPTO 10,000 PSIG (680 Bar) with Live Loaded PEEK Ball Seat which provides repeated Leak Tight shut-off and also compensate for wear and Pressure / Temperature fluctuations during its operations. These Valves are most suitable to be used in Fluid / Gas Control System in wide range of Industrial segment.

Construction & Features of Ball Valves with Live Load PEEK Seat

Features / Benefit :

- Available in Material SS316.

- Material traceable to certified material test report.

- Three piece body design.

- Low torque actuation bi-directional flow.

- Floating Ball design.

- Quarter turn positive stop handle.

- Every Valve is factory tested.

Product Range and Operating Parameters :

- Pressure Rating

(Ball Valve Series : VB41, VB43, VB45 & VB47) :UPTO 3000 PSIG (206 Bar) at CWP with PTFE Seat & Fluorocarbon / PTFE ‘O’ Ring - Pressure Rating

(Ball Valve Series : VB71, VB81, & VB91) :UPTO 10,000 PSIG (680 Bar) at CWP with PTFE Packing, PEEK Seat & Fluorocarbon ‘O’ Ring - Temperature Rating : -54o C to 180o C (depending on ‘O’ Ring material)

- End Connections -

- Fractional : 1/4” to 1” Tube OD

- Metric : 6mm to 25mm Tube OD

- Pipe Threads: 1/4” to 1” Male / Female BSP / BSPT / NPT

Applications :

- Hydraulic

- Gas

- Instrument Air Lines

- General Plant Service