DAWSONS-TECH most cost effective Needle Valve Series : NV101 is having compact and rugged Bar Stock Square Body design and construction. This Valve is most suitable for a variety of applications including Instrumentation, Hydraulic and Pneumatic systems.

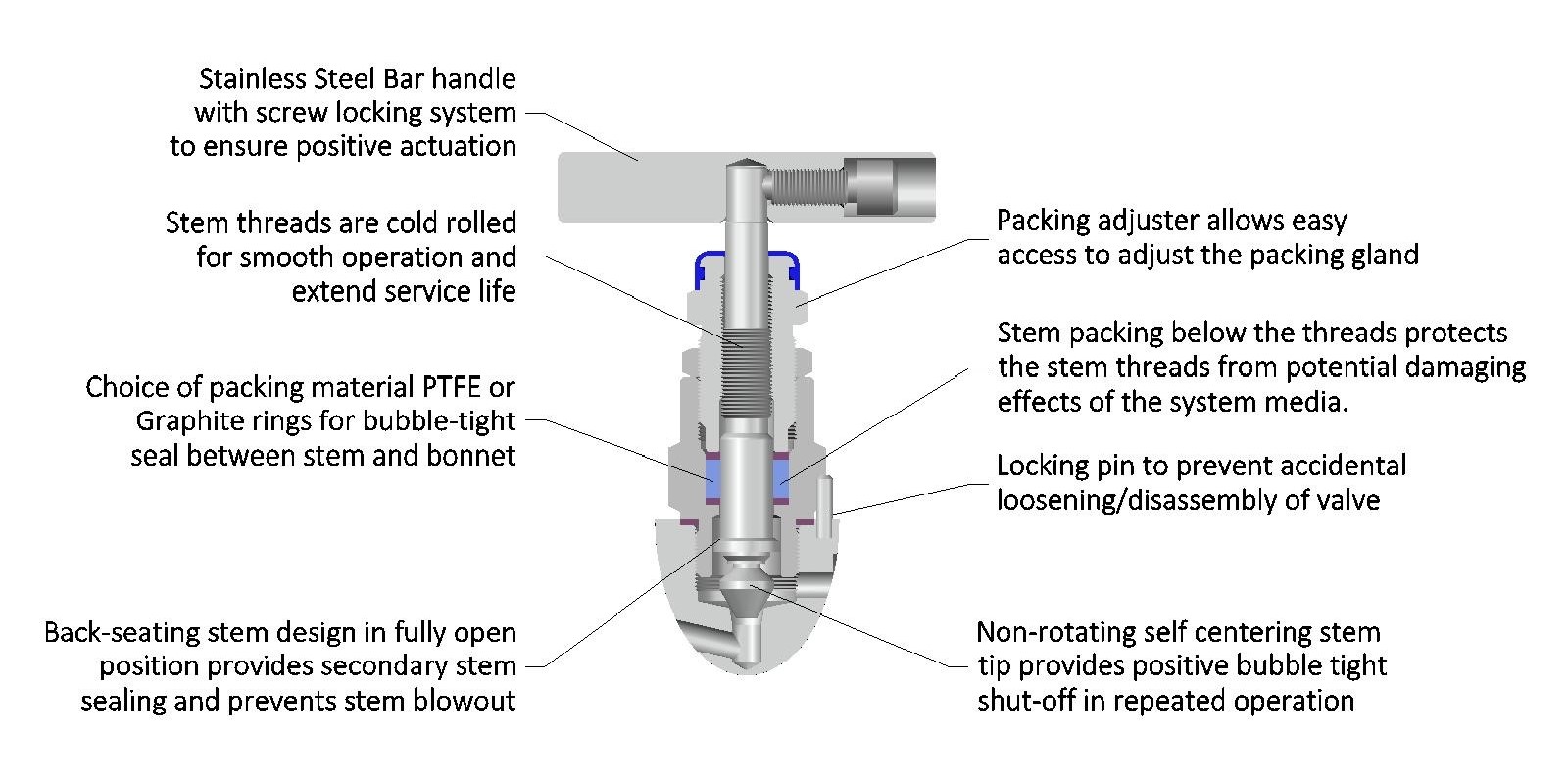

Features / Benefits :

- Low operating torque, Anti blow-out stem.

- Stem threads are cold rolled for smooth operation.

- Choice of optional stem to provide greater flexibility.

- Choice of packing PTFE or Graphite.

- Stem packing below the threads, protects the Stem threads from system media.

- Orifice size : 4.3mm, 6.3mm and 9.5mm, Flow Coefficient (Cv) from 0.37 to 1.8.

- Available in Material SS316, all wetted parts in accordance with NACE MR01-75.

- Every Valve is pressure tested.

Product Range & Operating Parameters :

- Pressure Rating : UPTO 6000 PSIG (413 Bar) at CWP.

- Temperature Rating :

- : -54° C to 232° C with PTFE Packing.

- : -96° C to 426° C with Graphite Packing.

- End Connections -

- Fractional : 1/4" to 1" Tube OD.

- Metric : 6mm to 16mm Tube OD.

- Pipe Threads : 1/4" to 3/4" Male / Female NPT, BSPT, BSP & Socket Weld

Applications :

- General Plant Services

- Hydraulic & Pneumatic

- Instrumentation Isolation,

- Pressure Measurement Devices

Stem Type :

DAWSONS-TECH Valves are available with choice of optional stem to provide greater flexibility.Non-Rotating (NR) : It is standard self-centering non-rotating stem tip typically used in high cycle application to extend the Valves life.

‘V’ Stem (VS) : It is used for general purpose liquid and gases.

Soft Seat (SF) : A soft seat stem requires a lower sealing torque. It is replaceable and suitable for temperature UPTO 120o C.

Regulating Stem (RS) : It is used where some degree of flow control required.

Technical Data :

The temperature and pressure rating for a standard Valve with PTFE packing.| Temperature | Pressure | |

| PSIG | Bar | |

| -54oC to 38oC | 6000 | 413 |

| -54oC to 93oC | 5160 | 351 |

| -54oC to 148oC | 4660 | 317 |

| -54oC to 204oC | 4280 | 291 |

| -54oC to 232oC | 4130 | 289 |

Type Test Approvals :

The design of DAWSONS-TECH Needle Valve Series : NV101 have been tested to Hydrostatic Proof & Burst Test in accordance to MSS SP-99-2016a Clause 5.5 & 5.6.Testing :

Certification :

The Certificate to 3.1 acc. to EN10204 for Valves body material and pressure test will be provided on request.Material of Constructions :

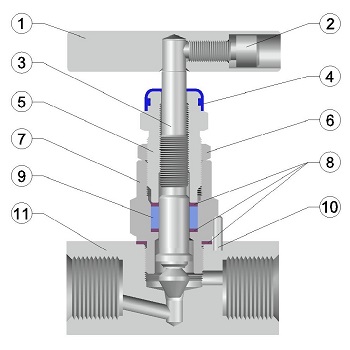

| Sr. No. | Part Description | Material |

| 1 | Handle | SS316 |

| 2 | Screw | SS316 |

| 3 | Valve Stem | SS316 |

| 4 | Dust Cap | PVC |

| 5 | Packing Adjustment Screw | SS316 |

| 6 | Lock Nut | SS316 |

| 7 | Bonnet | SS316 |

| 8 | Washer | SS316 |

| 9 | Packing | PTFE / Graphite |

| 10 | Safety Pin | SS316 |

| 11 | Valve Body | SS316 |

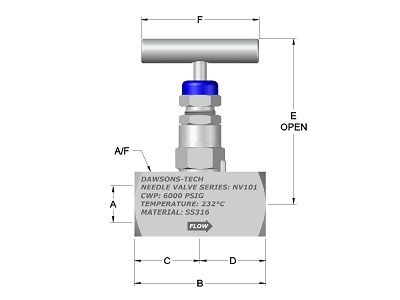

Standard Configuration Dimensions :

| End Connection | Flow Data | Dimensions In mm | Dawsons-TechPart No. | |||||||

| Type | Size - A | Orifice(mm) | Cv | B | C | D | E | F | A/F | |

| Tube OD to Tube OD(Fractional) | 1/4" | 4.3 | 0.37 | 72.8 | 36.4 | 36.4 | 79.0 | 54.0 | 25.40 | NV101-TT4 |

| 3/8” | 4.3 | 0.37 | 72.8 | 36.4 | 36.4 | 79.0 | 54.0 | 25.40 | NV101-TT6 | |

| 1/2" | 6.3 | 0.73 | 80.0 | 40.0 | 40.0 | 80.0 | 58.0 | 28.57 | NV101-TT8 | |

| 3/4" | 9.5 | 1.80 | 85.4 | 42.7 | 42.7 | 84.0 | 63.0 | 31.75 | NV101-TT12 | |

| Tube OD to Tube OD(Metric) | 6mm | 4.3 | 0.37 | 72.8 | 36.4 | 36.4 | 79.0 | 54.0 | 25.40 | NV101-TT6M |

| 8mm | 4.3 | 0.37 | 73.0 | 36.5 | 36.5 | 79.0 | 54.0 | 25.40 | NV101-TT8M | |

| 10mm | 6.3 | 0.73 | 73.2 | 36.6 | 36.6 | 80.0 | 54.0 | 28.57 | NV101-TT10M | |

| 12mm | 6.3 | 0.73 | 80.0 | 40.0 | 40.0 | 80.0 | 54.0 | 28.57 | NV101-TT12M | |

| Female to Female NPT | 1/4" | 4.3 | 0.37 | 58.0 | 29.0 | 29.0 | 79.0 | 54.0 | 25.40 | NV101-FF4N |

| 3/8” | 4.3 | 0.37 | 60.0 | 30.0 | 30.0 | 80.0 | 54.0 | 28.57 | NV101-FF6N | |

| 1/2" | 6.3 | 0.73 | 65.0 | 32.5 | 32.5 | 84.0 | 58.0 | 31.75 | NV101-FF8N | |

| 3/4" | 9.5 | 1.80 | 70.0 | 35.0 | 35.0 | 87.0 | 63.0 | 34.92 | NV101-FF12N | |

| 1” | 9.5 | 1.80 | 80.0 | 40.0 | 40.0 | 98.0 | 68.0 | 44.40 | NV101-FF16N | |

| Male to Female NPT | 1/4" | 4.3 | 0.37 | 60.0 | 31.0 | 29.0 | 79.0 | 54.0 | 25.40 | NV101-MF4N |

| 3/8” | 4.3 | 0.37 | 62.0 | 32.0 | 30.0 | 80.0 | 54.0 | 28.57 | NV101-MF6N | |

| 1/2" | 6.3 | 0.73 | 70.0 | 37.5 | 32.5 | 84.0 | 58.0 | 31.75 | NV101-MF8N | |

| 3/4" | 9.5 | 1.80 | 75.0 | 40.0 | 35.0 | 87.0 | 63.0 | 34.92 | NV101-MF12N | |

| 1” | 9.5 | 1.80 | 85.0 | 45.0 | 40.0 | 98.0 | 68.0 | 44.40 | NV101-MF16N | |

| Female to Female BSP | 1/4" | 4.3 | 0.37 | 58.0 | 29.0 | 29.0 | 79.0 | 54.0 | 25.40 | NV101-FF4RG |

| 3/8” | 4.3 | 0.37 | 60.0 | 30.0 | 30.0 | 80.0 | 54.0 | 28.57 | NV101-FF6RG | |

| 1/2" | 6.3 | 0.73 | 65.0 | 32.5 | 32.5 | 84.0 | 58.0 | 31.75 | NV101-FF8RG | |

| 3/4" | 9.5 | 1.80 | 70.0 | 35.0 | 35.0 | 87.0 | 63.0 | 34.92 | NV101-FF12RG | |

| 1” | 9.5 | 1.80 | 80.0 | 40.0 | 40.0 | 98.0 | 68.0 | 44.40 | NV101-FF16RG | |

| Socket Weld to Socket Weld | 1/4" | 4.3 | 0.37 | 58.0 | 29.0 | 29.0 | 79.0 | 54.0 | 25.40 | NV101-SW4 |

| 3/8” | 4.3 | 0.37 | 58.0 | 29.0 | 29.0 | 79.0 | 54.0 | 25.40 | NV101-SW6 | |

| 1/2" | 6.3 | 0.73 | 65.0 | 32.5 | 32.5 | 80.0 | 54.0 | 28.57 | NV101-SW8 | |

| 3/4" | 6.3 | 0.73 | 70.0 | 35.0 | 35.0 | 84.0 | 58.0 | 31.75 | NV101-SW12 | |