DAWSONS-TECH SAE ‘O’ Ring Face Seal Fittings (ORFS) are very versatile fluid connectors for liquids and gases from Vacuum to 6000 PSIG and works exceptionally in such applications.

ORFS are “Zero tolerance / clearance Fittings” and hence, can be inserted and removed from its position in the systems without requirement of cutting or flexing the pipe or tube making them ideal for systems requiring frequent maintenance / replacement for Valves and other components.

ORFS are “Zero tolerance / clearance Fittings” and hence, can be inserted and removed from its position in the systems without requirement of cutting or flexing the pipe or tube making them ideal for systems requiring frequent maintenance / replacement for Valves and other components.

Features / Benefits :

- Zero tolerance / clearance system - No requirement of cutting or flexing the tubing to insert or remove Fittings, Valves or other components for installations and repeat maintenance.

- Unlimited remakes - ORF Fittings can be disassembled and reassembled many times by simply replacing the 'O’ Ring and tightened its recommended torque.

- Assembly Adaptability - Soft seal Fittings (ORF) adjust to irregularities in the Fitting face or Sleeve.

- Available in Material SS316L.

Product Range & Operating Parameters :

- Pressure Rating : Vacuum 6000 PSIG (413 BAR) at CWP.

- Temperature Rating : Upto 204o C.

- End Connections -

- Fractional : 1/4" to 1" ORF Tube OD.

- Metric : 6mm to 25mm ORF Tube OD.

- Pipe Threads : 1/8” to 1” Male / Female SAE, NPT & BSPT

Applications :

- Gas Delivery System

- Instrumentation in Semiconductor Industries

- Vacuum

How Soft-Seal ‘O’ Ring Face Seal Fittings Work :

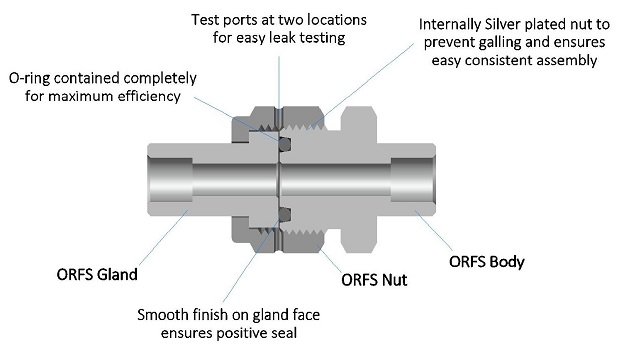

Soft-seal ‘O’ Ring Face Seal Fitting assembly consists of four parts i.e. threaded Fitting body with ‘O’ Ring grooves, ‘O’ Ring, Nut and Sleeve or tailpiece. The standard ‘O’ Ring material is Buna-N, but other materials ‘O’ Rings are also offered which are tested and compatible for special applications.The Fitting assembly seals when the bottom of the Sleeve or tailpiece, which are been fixed to the Tubing, compresses the ‘O’ Ring in the face of the threaded Fitting body when the Fitting Nut is threaded onto the external threads of the Fittings body. The threading action brings the Sleeve to full contact with the face of the Fitting. The Sleeve or the tailpiece is secured to the Tubing either by welding, Brazing or Mechanically by Flanging the Tubing.

| Installation Torque | ||

| Size | Tube OD(Inch) | Torque (in./lb.) |

| -4 | 1/4 | 20 - 40 |

| -6 | 3/8 | 25 - 50 |

| -8 | 1/2 | 40 - 75 |

| -10 | 5/8 | 60 - 120 |

| -12 | 3/4 | 110 - 220 |

| -16 | 1 | 180 - 350 |

Typical Applications for Soft-Seal Tube Fittings :

Soft-Seal Tube Fittings are highly recommended on high vibration systems and since the Soft-Seal absorbs shock better than any metallic (Metal to Metal) sealing system.While the SAE Soft-Seal were used in off-road construction machinery, it is now widely encouraged in other transportation related applications such as Alternate Fuel Systems (LPG / CNG) for vehicles. It is also endorsed by ISO Technical committee 131 for all new Hydraulic system design.