DAWSONS-TECH 37o Flared Tube Fittings are compact and simple in design for assembly and assures maximum reliability and performance. It is especially suited for low and medium wall tubing with good vibration resistance in a broad selection of types and sizes. It is used in virtually every application that uses Fluid Power for motion control & Automation.

Features / Benefit :

- 37o angle and seat design according to SAE J514 / ISO 8434-2.

- Usable with Metric or Fractional Tubes.

- Vibration Resistance.

- Usable Hose Connection.

- Available in Material SS316.

Product Range & Operating Parameters :

- Pressure Rating : UPTO 5000 PSIG (344 BAR) at CWP

- Temperature Rating : UPTO 426o C.

- End Connections - Fractional : 1/8” to 1” Tube OD

- Metric : 6mm to 25mm Tube OD

- Pipe Threads: 1/8” to 1” BSP / BSPT / NPT & SAE.

Applications :

- Hydraulic

- Pneumatic, etc.

Design :

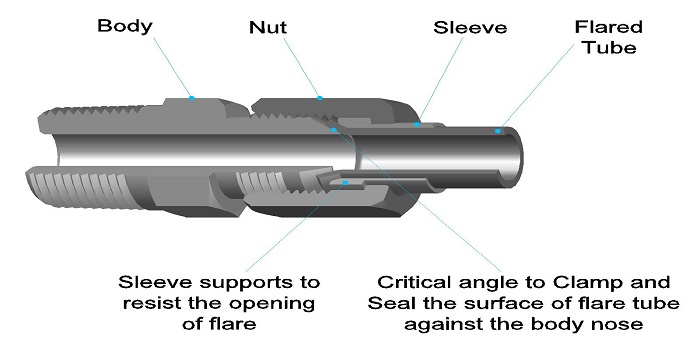

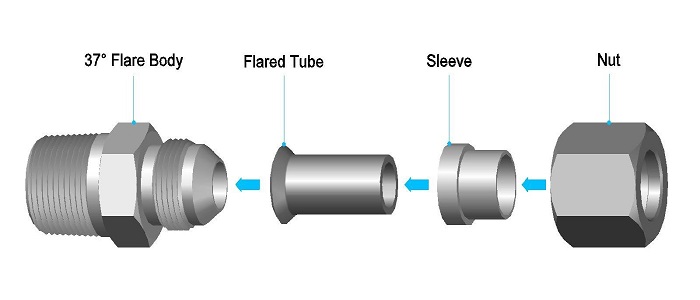

DAWSONS-TECH 37o Flared Tube Fittings consist of three precision components such as Body, Sleeve & Nut. These components have been manufactured to every stringent tolerance under rigid quality control procedure approved to ISO 9001:2015.

DAWSONS-TECH 37o Flared Tube Fittings meets SAE J514 Standard.

The Tube end is flared at a 37o angle and sandwiched between the Fitting Body Nose (Seat) and the Sleeve with Nut, which provide a very effective leak free joint, full flow connection process Tubing.

DAWSONS-TECH 37o Flared Tube Fittings are available as a standard in SS316 material, which meets the following specifications.

B. SS316 FORGING: ASTM A-182

Other materials are available on request.

Pressure Rating :

DAWSONS-TECH 37o Flared Tube Fittings provide zero leakage, full flow connection in Hydraulic System operating at working pressure as specified below.Allowable working pressure ratings are based on min. design factor 4:1 for dynamic and 3:1 for static application.

| Nom. Tube ODInch | 37o FlareStraight Thread | Nom. Pipe SizeInch | SAE St. ThreadsUnion and Bulkhead | Fittings with Pipe Thread |

| 1/8 | 5/16 x 24 | 1/8 | 5000 | 5000 |

| 3/16 | 3/8 x 24 | 1/8 | 5000 | 5000 |

| 1/4 | 7/16 x 20 | 1/8 | 5000 | 5000 |

| 5/16 | 1/2 x 20 | 1/8 | 5000 | 5000 |

| 3/8 | 9/16 x 18 | 1/4 | 5000 | 5000 |

| 1/2 | 3/4 x 16 | 3/8 | 4500 | 4000 |

| 5/8 | 7/8 x 14 | 1/2 | 3500 | 3000 |

| 3/4 | 7-1/76 x 12 | 3/4 | 3500 | 3000 |

| 7/8 | 1-3/16 x 12 | 3/4 | 3000 | 2500 |

| 1 | 1-5/16 x 12 | 1 | 3000 | 2000 |

Available Sizes :

Fractional Size: Ranges from 1/8” to 1”Metric Size: Ranges from 6mm to 25mm

Quality of Tubing :

Stainless Steel 316 or 304 seamless tubing should be fully annealed, according to Standard ASTM-269 suitable for bending and flaring. Length of finished tubing shall be reasonable straight and have smooth ends and free from burrs, scales and any kind of defect and scratches.Assembly Instruction :

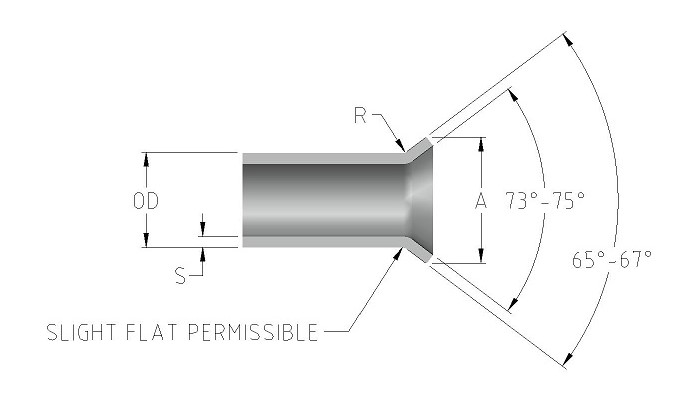

Flare the Tube with a special flaring tool to 37o, dimensions of Flared Tube according to SAE J533 standard as shown below.

The Dimensions of the Flared Tube according to SAE J533 are as below :

| Nominal Tube OD Inch | ASingle Flare Diameter | R | S | |||||

| Inch | mm | Inch | mm | Inch | mm | |||

| Max. | Min. | Max. | Min. | ±0.2 | ±0.5 | ±0.2 | ±0.5 | |

| 1/8 | 0.20 | 0.18 | 5.08 | 4.58 | 0.03 | 0.8 | 0.035 | 0.88 |

| 3/16 | 0.28 | 0.26 | 7.11 | 6.61 | 0.03 | 0.8 | 0.035 | 0.88 |

| 1/4 | 0.36 | 0.34 | 9.14 | 8.64 | 0.03 | 0.8 | 0.065 | 1.65 |

| 5/16 | 0.43 | 0.40 | 10.92 | 10.16 | 0.03 | 0.8 | 0.065 | 1.65 |

| 3/8 | 0.49 | 0.46 | 12.44 | 11.69 | 0.04 | 1.0 | 0.065 | 1.65 |

| 1/2 | 0.66 | 0.63 | 16.76 | 16.01 | 0.06 | 1.5 | 0.083 | 2.10 |

| 5/8 | 0.79 | 0.76 | 20.06 | 19.31 | 0.06 | 1.5 | 0.095 | 2.41 |

| 3/4 | 0.95 | 0.92 | 24.13 | 23.37 | 0.08 | 2.0 | 0.109 | 2.76 |

| 7/8 | 1.07 | 1.04 | 27.17 | 26.42 | 0.08 | 2.0 | 0.109 | 2.76 |

| 1 | 1.20 | 1.17 | 30.48 | 29.72 | 0.09 | 2.3 | 0.120 | 3.04 |